D-F 130mm (5-1/8”) Conventional DRO Table Type Horizontal Boring and Milling Machine - Model TPX6113

Boring Mills, Horizontal, Table Type

D-F 130mm (5-1/8”) Conventional DRO Table Type Horizontal Boring and Milling Machine - Model TPX6113

| Spindle Size | 5.125" |

| X-Horiz Tvl of Table | 80" |

| Y-Vert Tvl of Head | 70" |

| Power | 37 hp |

| RPM | 1,000 RPM |

| Table-W | 63" |

| Table-L | 71" |

D-F 130mm (5-1/8”) Conventional DRO Table Type Horizontal Boring and Milling Machine - Model TPX6113

Technical Information

Features:

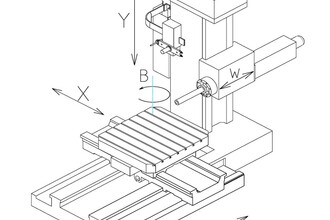

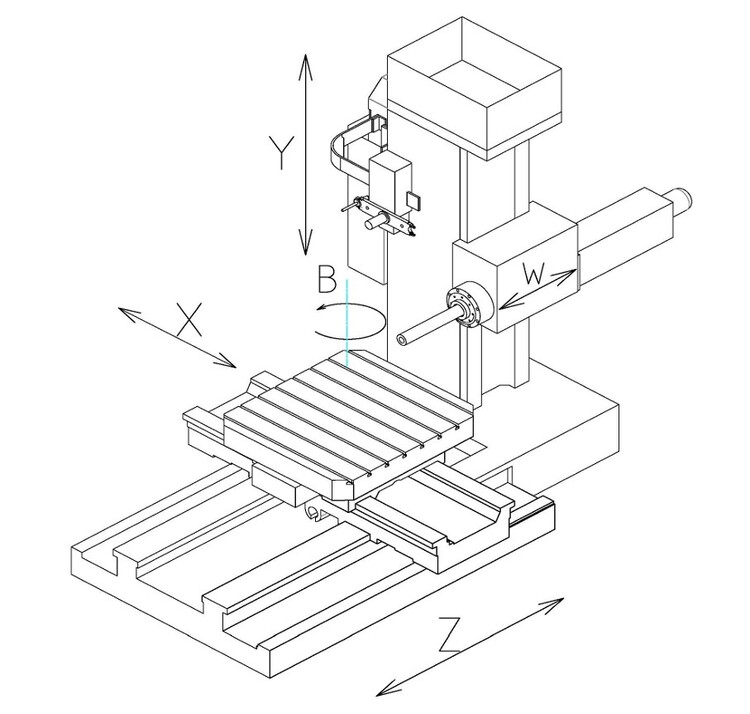

★ X, Y, Z, B axis has the DRO system.

★Worktable servo indexing in 0.001 degree by B axis DRO

★ X, Y, Z, W axis with servo motor and ballscrew

★ BT50 spindle nose with hydraulic clamp tool

★ Spindle motor use CTB servo motor with Danfoss/ABB drive

★ Z axis with additional support guideways, bed body casting in one piece

★ High rigidity spindle could insure the strong machining.

★ Siemens/Schneider electric units in electric cabinet-Option

1, Introduce

The horizontal boring and milling machine series TPX series of our company is the finish machining equipment in the universal machine. It is suitable for such operation as drilling, counter-boring, boring, reaming, spot-facing, and milling etc. Also the horizontal boring and milling machine type is equipped with fixed facing head on which radial facing slide can be radically feed consequently to enable the machine to undertake boring of large-diameter hole, external cutting ,end face turning and recessing, etc.

The machine is composed of bed, front column, headstock, cross and longitudinal saddle, worktable, and balance weight pulley etc. Their motions are the headstock moves vertically along the column's guideway, the worktable can move transversely and longitudinally on the bed, and the worktable can rotate.

2. The characteristics of TPX series:

1)The speed change of main motion and feed motion of the machine are all adopted hydraulic pre-selection centralized control which operation is simple and convenient. The indicator lamps are lighted up to give the signal during the course of speed and feed changing.

2)The vertical coordinate(headstock lifting direction)and cross coordinate(worktable transverse movement)and longitudinal coordinate(worktable longitudinal movement, supplied according to the custom's requirement)are provided with new type Digital Unit with memory function, which makes the machine with complete function and high accuracy.

3 Main parts of the machine such as bed, front column and guideways of longitudinal saddle are all adopted electric-contract surface heating self-cooling harden, which bring high stiffness of the guideways and extend the using life of the machine.

4) The horizontal guideway surface of the machine is provided with all pull-board type dust-proof.

3. Transmission systems of the machine

X axis: Servo motor with ballscrew

Y axis: Servo motor with ballscrew

Z axis: Servo motor with ballscrew

W axis: Servo motor with ballscrew

B axis: Servo motor with gearbox for indexing

4. Electrical system

A reliable & optimized electrical system is adopted on the machine. All the electrical components, except the travel limit switches, high / low range feed switches, braking switch of the tool head, locate in the electric cabinet. All other operations, like movement, lubrication, lightening, etc locate on the operation panel for easier operation.

○ Big electric cabinet for easier operation and maintenance.

○ OMRON/SIEMENS brand PLC unit is equipped for reliable electrical control.

○ Neat wiring and enclosed cabinet to keep away of intrusion of dusts, humidity, etc.

5. Hydraulic system of the machine

The hydraulic system of this kind of machine is composed of two parts: One is in the tail bracket and upper and inner part of headstock which is used for spindle speed change and feed speed change and headstock internal lubrication. Another is in the inner part of longitudinal saddle of the machine, which is used for the transverse of headstock, longitudinal & cross movement and rotation of worktable Hydraulic system of main transmission、feed speed change and internal lubrication of headstock.

6. Digital readout-DRO-SINO

Our standard machine is with 4 axis DRO

X axis: with DRO

Y axis: with DRO

Z axis: with DRO

B axis: with DRO

W axis: with DRO-Option

7, Main Specifications

Specifications Unit TPX6113F1 TPX6113F2

Spindle diameter mm 130

Spindle Taper BT50/ISO50

Spindle tool clamping Hydraulic by button

Max. Spindle Torque N. m 3100

Max. axis resistance of Spindle N 31000

Speed range of spindle rpm 1000

Spindle speed range steps 2

Power of Spindle motor-Servo motor KW 30

Max.torque of facing head N.m 4900

Facing head diameter mm 630

Speed range of facing head rpm 2.5-125

Table size(L × W) mm 1600×1400 1800x1600

Max. load of table ton 8

T-slot size mm 28

X-axis travel mm 1800 2000

Y-axis travel mm 1600 1800

Z-axis travel mm 1500 1500

W-axis travel mm 800 800

U-axis travel(Slide of facing head travel) mm 200 200

Worktable indexing in each 90 degree 90°x 4

Min. distance between spindle axis and table surface mm 0

Rapid travel(X/Y/Z) mm/min 2500

8. Components on machine

Item Brands

PLC control Omron-Japan/Siemens-Germany

Electric units in cabinet Tianshui 213-CE standard

DRO for X, Y, Z axis Sino

DRO for B axis indexing Sino

Servo motor for X, Y, Z, W axis Huada/CTB

Servo motor for worktable indexing-B axis Huada/CTB

Drive for Servo motor of X, Y, Z, W, B Maxsine

Servo motor for spindle CTB

Drive for spindle motor Danfoss/ABB

X axis Ballscrew LTM/TBI

Y axis Ballscrew LTM/TBI

Z axis Ballscrew LTM/TBI

W axis Ballscrew LTM/TBI

Bearing for ballscrew INA/NSK

Spindle bearing FAG/SKF

Main hydraulic units Kompass-Taiwan

Air condition for electric cabinet-Option Tongfei/Labor